The production departments: the heart of the production process

The processing departments represent the central element of the production organization of a modern foundry, as they determine the final quality of the iron castings and the efficiency of the entire industrial cycle.

Within the Fonderia Quaglia & Colombo, located in Legnano (Milan), the departments are structured to ensure constant monitoring of each phase, from the preparation of the molds to the final checks on the materials produced.

The integration of automated systems and manual processes allows us to precisely meet diverse production needs, both for small runs and large components. The presence of specialized departments, supported by reliable technology and qualified personnel, allows us to maintain high standards and production continuity, while adhering to the technical specifications required by the relevant industrial sector.

Contact us for information or a personalized quote!

EN ISO 9001 QUALITY CERTIFICATION

The Fonderia Quaglia & Colombo operates according to an EN ISO 9001 certified management system, which guarantees process control, manufacturing traceability, and product compliance with required standards.

This certification directly involves all production departments, ensuring shared procedures, systematic checks, and a quality-oriented approach.

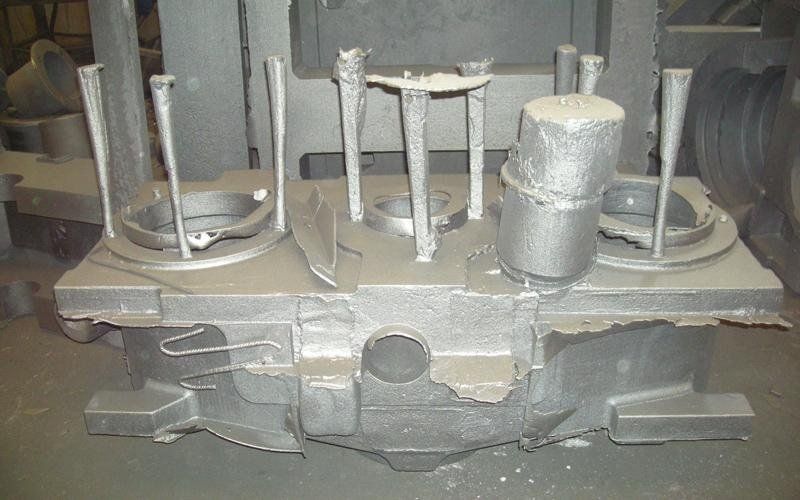

- Automatic No-Bake Molding: This highly versatile system allows for the simultaneous production of up to four different models. Thanks to its mold molding technology, it adapts perfectly to the size of even very different castings. The maximum mold size is 1770 x 1600 x 650 650 mm, and castings weighing up to 1300 kg can be cast.

- No Bake Manual Moulding: the manual moulding department is intended for the production of large castings or very small batches, it is equipped with a 20 Ton/h continuous mixer and a large range of moulds with dimensions up to 4500X2000

- Automatic green casting: this system is intended for the production of small and medium series castings, it is equipped with a shock wave moulder, 4 casting lines and can produce up to 45 moulds/h, the mould dimensions are 860X580X300 300 and it is possible to cast parts weighing up to 100 kg

- Smelting department: Our cast irons are produced in two 5-ton and 15-ton electric induction furnaces, guaranteeing a production capacity of 4,000 tons/year. Learn more about the cast iron smelting process.

- Core production: our core production department is equipped with a 5 Ton/h continuous mixer for the formation of cores using the No Bake system. Core production using cold-box and shell-moulding systems is outsourced to qualified suppliers.

- Laboratory: We are equipped to provide customers with all the chemical and physical characteristics of the materials we produce: chemical analysis, hardness, tensile strength, yield strength, elongation, impact strength, and toughness. Any non-destructive testing such as US, MT, X-ray, etc., is performed by qualified external laboratories.

- Modeling: The construction of new models is entrusted to external modeling shops with whom we have collaborated for years and equipped with CNC machines. For any modifications, re-plating, and routine and extraordinary maintenance, we have a traditional modeling shop where specialized technicians produce everything with the utmost precision.