Rectangular cast iron bars

Rectangular cast iron bars represent a reliable technical solution for numerous industrial applications requiring dimensional precision, structural stability and consistent material quality.

Fonderia Quaglia & Colombo has been selling rectangular cast iron bars since the 1970s, gaining extensive experience that accompanies the evolution of production technologies and the needs of the mechanical and manufacturing sectors.

Thanks to the use of continuous casting in spheroidal cast iron and flake cast iron, it is now possible to offer a final product of the highest quality: homogeneous, free of internal porosity and also suitable for replacing components traditionally made of steel.

Contact us

for information

or a personalized quote!

Production of continuously cast iron rectangular bars

Continuous casting is a production process that produces rectangular cast iron bars with consistent metallurgical characteristics throughout their entire cross-section. This system allows for precise control of solidification, reducing internal defects and ensuring a compact and uniform structure.

The bars are produced both in flake cast iron, appreciated for its damping properties and workability, and in spheroidal cast iron, known for its high mechanical strength and good ductility.

Thanks to this process, the final material is particularly suitable for subsequent mechanical processing, maintaining precise tolerances and a predictable response to removal operations.

CONTINUOUS CASTING IN SPHEROIDAL AND FLAKE CAST IRON

Technical features and application advantages

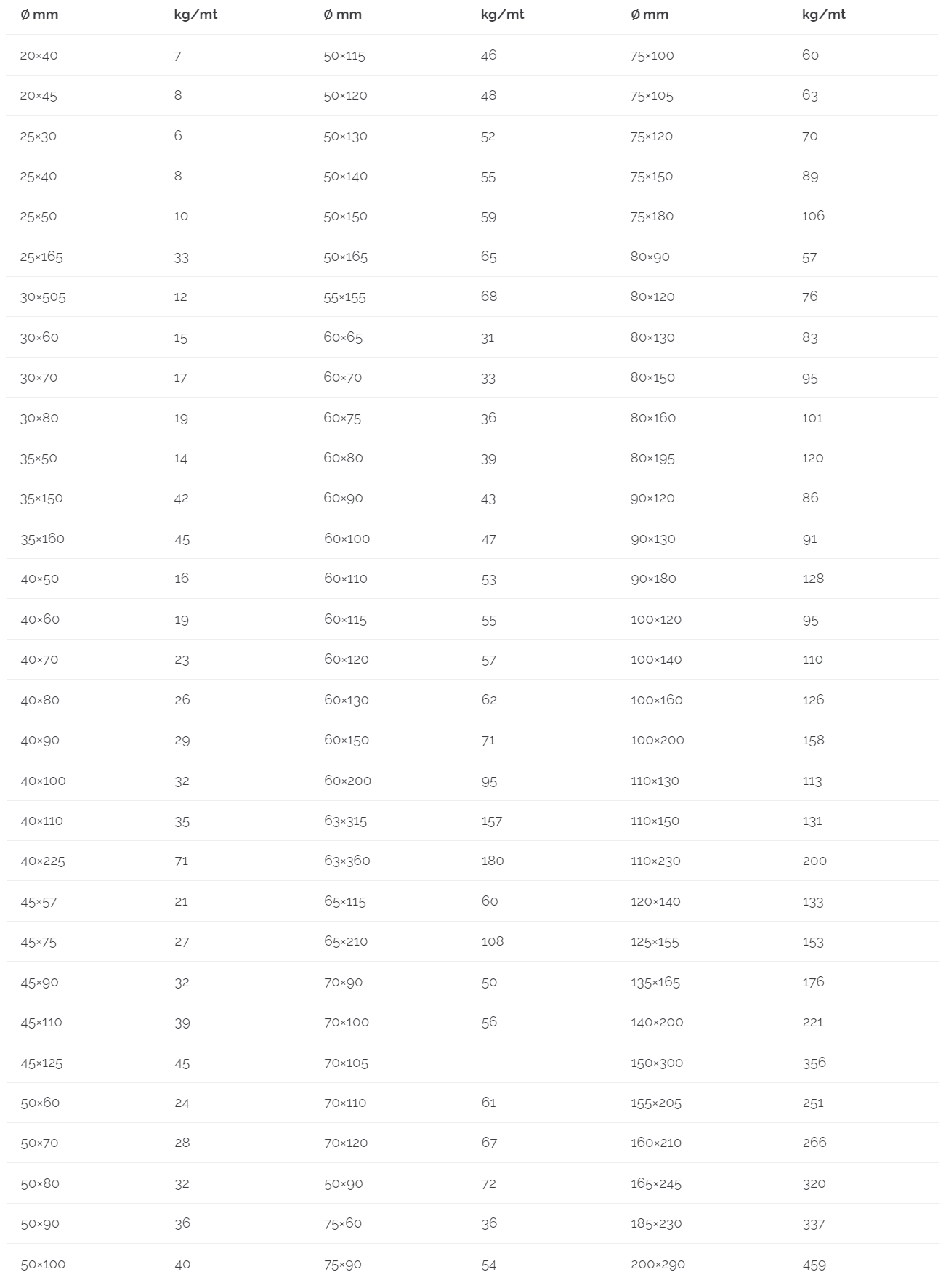

Rectangular cast iron bars are distinguished by a series of characteristics that make them suitable for a variety of industrial applications. Among the most notable aspects are dimensional stability, the absence of internal blowholes, and the material's structural continuity. These elements help reduce waste and rework during subsequent production phases. From an application standpoint, rectangular cast iron bars are used in the production of mechanical components, bases, guides, plates, and structural parts for industrial machinery. In many cases, the quality achieved through continuous casting allows cast iron to be considered a valid alternative to steel, especially when good mechanical performance combined with ease of workability is required.

Our warehouse is always well-stocked, but if the requested size isn't available, we can procure the material within a week. For specifications on the alloys used, please also consult the Cast Iron section of the website.

FAQ

What are continuously cast rectangular cast iron bars?

They are semi-finished products obtained through a process that guarantees a compact structure, absence of internal porosity and constant mechanical characteristics.

What is the difference between lamellar cast iron and ductile cast iron?

Lamellar cast iron offers excellent machinability and damping capacity, while ductile cast iron guarantees greater mechanical strength and ductility.

Are rectangular cast iron bars available in stock?

Yes, the warehouse is generally well stocked with standard sizes ready for delivery.

How long does it take for an unavailable measurement?

If the sizes are not in stock, the material can be obtained within approximately one week.

Can rectangular cast iron bars be used instead of steel?

In many applications, yes, especially when good mechanical performance combined with ease of processing is required.