LAMINATED IRON FOUNDRY

A flake cast iron foundry, commonly called gray iron, is an iron-carbon alloy in which the carbon is present in the form of flakes. These flakes, arranged in a matrix of ferrite or pearlite, give gray iron a series of distinctive properties that make it particularly suitable for numerous industrial applications. Thanks to its lamellar structure, gray iron offers good vibration damping capacity, a key feature for reducing wear and noise in machinery. Furthermore, it has a reasonable resistance to wear, making it useful in harsh working environments or where repeated contact between components occurs.

Lamellar iron foundries play a crucial role in modern industry, producing this alloy, which, in addition to boasting excellent mechanical properties, is distinguished by its relatively low cost. Compared to other metallic materials, this alloy represents the most economical solution in mechanical engineering, combining affordability with good mechanical properties.

It is widely used in the production of essential components such as machine bases, cylinders, and engine blocks, which require both dimensional stability and the ability to withstand mechanical and thermal stress. Its relatively easy workability, combined with its good adaptability to casting processes, further contributes to its widespread use in industry.

Contact us for information or a personalized quote!

What is lamellar cast iron and how is it obtained?

Flake cast iron is an alloy obtained through a casting process in which the chemical composition and cooling conditions favor the formation of graphite in flake form. These flakes interrupt the continuity of the metal matrix, directly influencing the mechanical behavior of the material. Controlling the temperature, composition, and solidification times allows for a homogeneous and stable structure, essential for ensuring consistent performance in the final components.

During the production process, the cast iron is poured into molds designed to meet the dimensional and functional specifications of the part. This allows for the creation of complex components while maintaining a good balance between mechanical strength, geometric precision, and production repeatability.

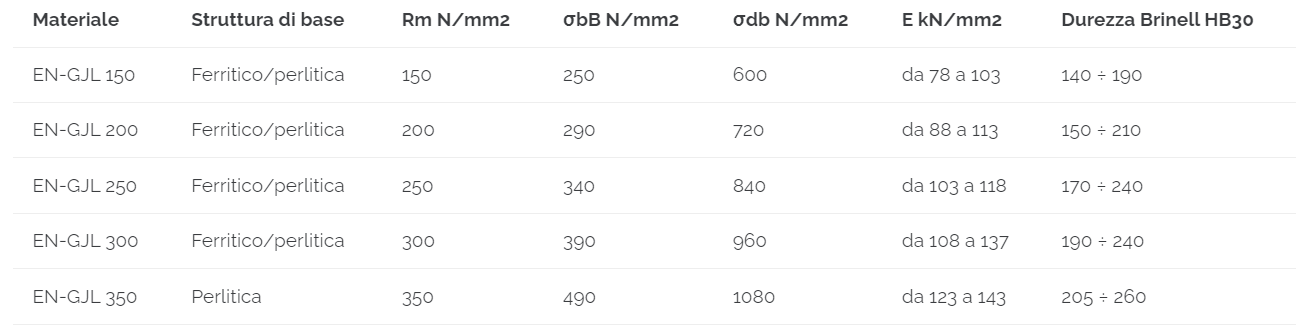

The characteristics of lamellar cast iron

In a lamellar iron foundry, it is essential that the cast iron exhibits characteristics such as compressive strength, shear strength, and wear resistance, as well as good rigidity and high vibration damping capacity. These qualities, combined with excellent machinability, make gray iron a highly versatile material that, when used correctly, offers designers effective and innovative solutions to address a variety of design challenges.

Gray cast irons find application in a wide range of sectors, thanks to their ability to adapt to multiple needs. Furthermore, through various casting techniques, it is possible to achieve different aesthetic and structural characteristics, customizing the material according to specific project requirements. This process optimizes the performance of the finished product, making lamellar cast iron a reliable and flexible choice for numerous industrial applications.

Discover the art of blending tradition and innovation at our lamellar iron foundry. Trust our passion and quality for safe, cutting-edge solutions!

FAQ

What is the difference between lamellar cast iron and other types of cast iron?

Lamellar cast iron is characterised by graphite in the form of lamellae, while other cast irons have spheroidal or compact graphite, with different mechanical behaviours.

Is lamellar cast iron suitable for components subject to vibration?

Yes, thanks to its high vibration damping capacity, it is suitable for machine bases and structures.

In which sectors is grey cast iron used?

It is mainly used in the mechanical, automotive, machine tool and industrial plant engineering industries.

Is lamellar cast iron easy to work with?

It has good machinability, allowing turning and milling operations with precise results.

Is it possible to customize the characteristics of lamellar cast iron?

Yes, by varying the chemical composition and melting process, it is possible to adapt the material's properties to the needs of the project.