Cast iron square bars

Cast iron square bars represent a consolidated technical solution for numerous industrial applications requiring dimensional reliability, structural uniformity and good mechanical performance.

Fonderia Quaglia & Colombo has been operating in this field since the 1970s, marketing bars obtained through continuous casting of spheroidal and flake cast iron, a technology that has evolved over time to guarantee high and consistent quality standards.

Thanks to decades of experience in the cast iron industry, the company is able to offer a product free from internal defects, characterized by a compact and homogeneous structure, suitable even for complex mechanical processes. Cast iron square bars are used in a variety of production contexts and, in specific applications, can represent an effective technical alternative to steel.

Contact us for information or a personalized quote!

Production of continuously cast iron square bars

The production of cast iron square bars takes place through the continuous casting process, a technology that allows for the production of semi-finished products with high metallurgical stability and geometric precision.

This system allows for controlled cooling of the material, minimizing the presence of porosity, blowholes or internal discontinuities.

The result is a bar with a uniform structure along its entire cross-section, a key feature for ensuring consistent performance during subsequent processing. The continuity of the production process also allows for greater product repeatability, a key factor for industrial supplies.

CONTINUOUS CASTING IN SPHEROIDAL AND FLAKE CAST IRON

Technical characteristics of the square bars

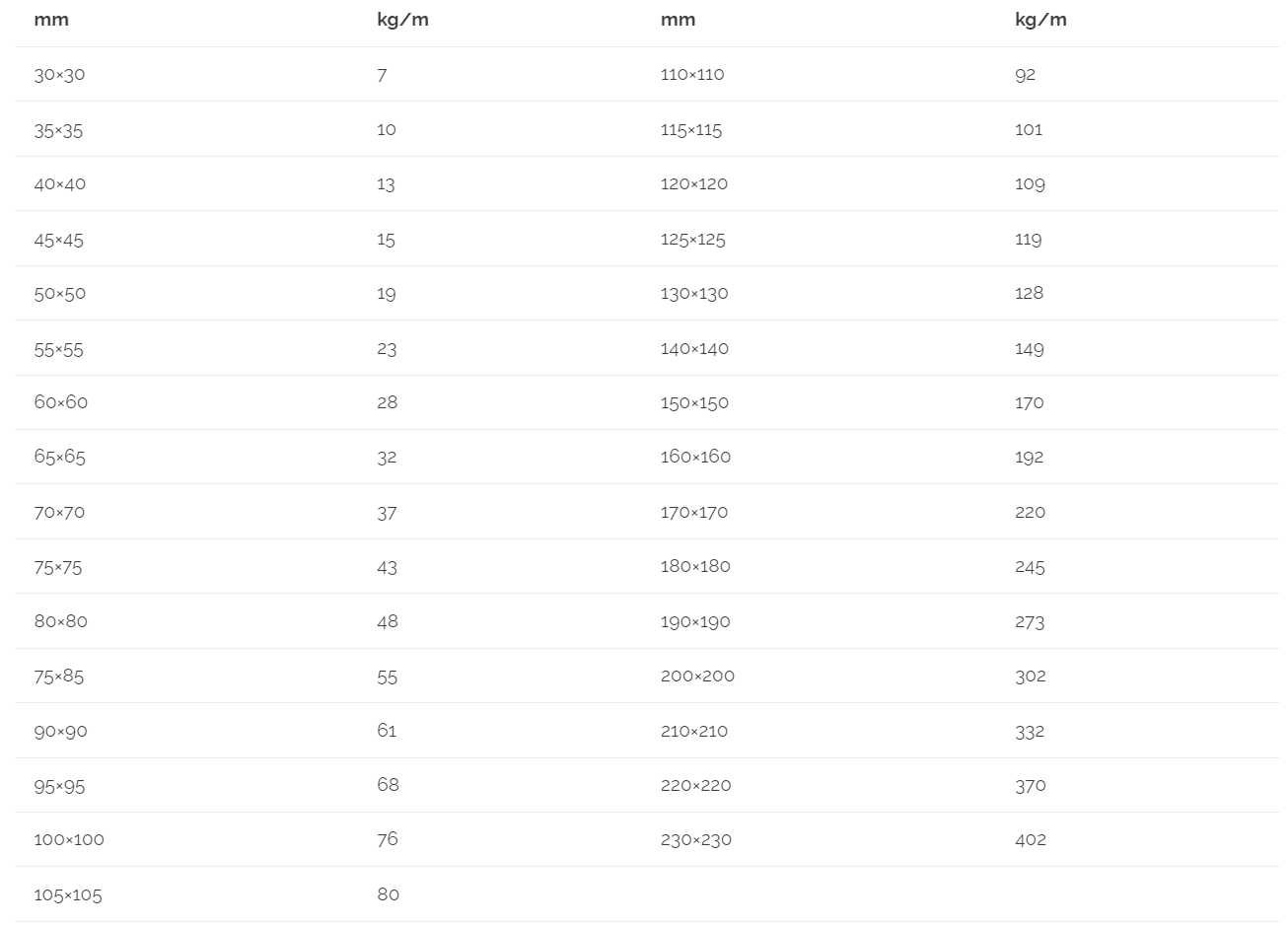

The cast iron square bars offered by Fonderia Quaglia & Colombo are available in ductile iron and lamellar iron, two materials with different characteristics, chosen based on application needs.

Lamellar cast iron, also known as gray cast iron, is prized for its good machinability, vibration damping, and dimensional stability. It is suitable for components subjected to moderate loads and for applications requiring a good surface finish.

Ductile cast iron, on the other hand, offers superior mechanical properties, such as tensile strength and toughness, making it suitable for more demanding applications. In many cases, ductile cast iron square bars can replace steel elements, maintaining advantages in terms of workability and production costs.

Our warehouse is always well-stocked, but if the requested size is not available, we can procure the material within a week.

For detailed information on the chemical compositions and specifications of the alloys used, please refer to the section dedicated to Cast Irons.

FAQ

What are continuously cast iron square bars?

They are semi-finished products obtained through a continuous process that guarantees a homogeneous structure, dimensional precision and the absence of internal defects.

What is the difference between ductile iron and lamellar iron square bars?

Lamellar cast iron offers good machinability and vibration damping, while ductile cast iron guarantees greater mechanical strength.

Can cast iron square bars replace steel?

In some applications, yes, especially when good mechanical performance combined with easier workability is required.

Are cast iron square bars available in stock?

Yes, many sizes are always in stock. Otherwise, delivery generally occurs within a week.

Where can I find the specifications of the alloys used?

Technical information on the alloys can be found in the cast iron section of the website.