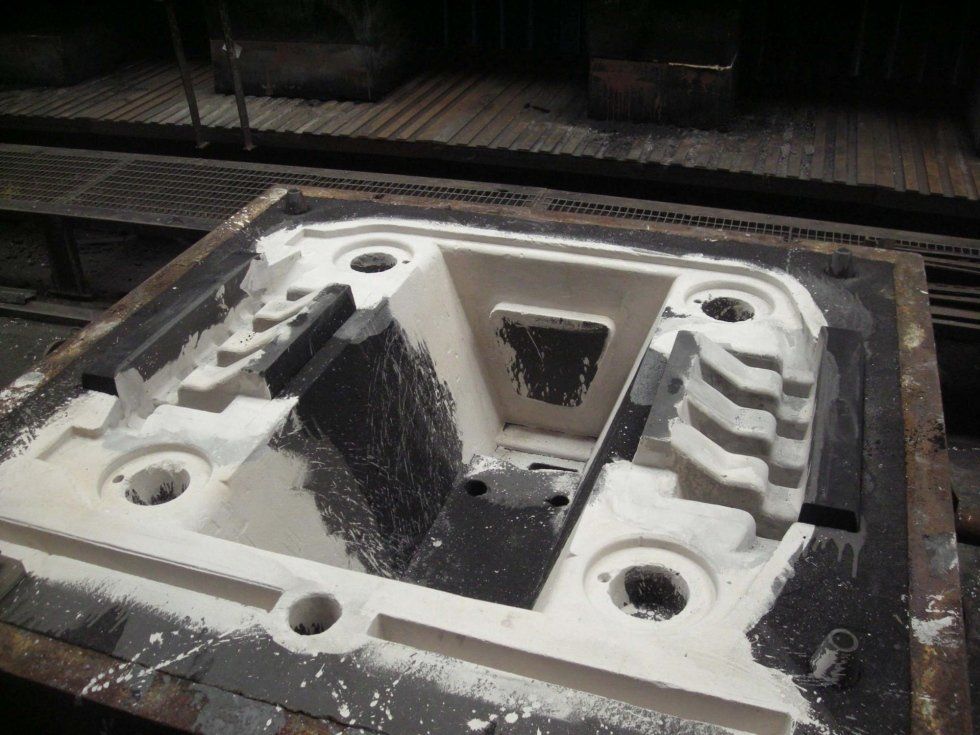

No Bake manual moulding for large and complex castings

No-Bake manual casting represents one of the most advanced and flexible technologies in the casting industry, particularly suitable for producing large-scale castings or for production of very small batches. This process achieves high levels of geometric precision, dimensional stability, and quality control, even for particularly complex castings. Within the Fonderia Quaglia & Colombo, No-Bake manual casting is a strategic department, where technology and artisanal expertise combine to meet the most specific production needs.

Contact us for information or a personalized quote!

No-Bake Manual Forming Department

HIGH QUALITY PRODUCTION WITH THE NO-BAKE PROCESS

The manual molding department at the Fonderia Quaglia & Colombo, equipped with a continuous mixer with a capacity of 20 tons per hour, is designed for the production of large castings or very small batches.

The large selection of brackets available allows us to meet every need in terms of shapes and sizes for castings weighing up to 6 tons.

This department is designed to ensure maximum operational flexibility: the molds are handcrafted using cold-bonded sands, which ensure high mechanical strength and a consistent surface finish. Manual, no-bake molding also allows for the management of complex geometries, articulated cores, and varying thicknesses, maintaining full control over every stage of the process.

Even today, when technology has allowed us to automate nearly all production, for the most complicated and largest castings we rely exclusively on the experience of our molders and molders. The Fonderia Quaglia & Colombo mission has always been, and will always be, to ensure the highest quality in every process. Human intervention remains a key element, especially when advanced technical skills and in-depth knowledge of the materials are required.

Technical characteristics of the No Bake manual moulding

No-Bake manual shaping stands out for a series of features that make it particularly suitable for special and customized productions. Among the most significant aspects are:

- use of self-leveling sands with controlled hardening chemical binders

- high dimensional stability of shapes even for large volumes

- possibility of producing single castings or small series without plant constraints

- reduction of surface defects thanks to greater care in the preparation of the forms.

These elements allow for reliable, repeatable castings that are consistent with the required technical specifications, even in complex production contexts.

Constant technological and productive improvement

Throughout its 60-year history, the Milanese company, founded in the 1930s, has consistently focused on technological and production improvements, offering every customer the greatest possible range of services, without compromising on quality.

This approach has allowed Fonderia Quaglia & Colombo to integrate the tradition of manual No Bake molding with advanced technical solutions, advanced control tools, and optimized production process management, maintaining high quality standards over time.

FAQ

What is No-Bake Hand Forming?

It is a forming process that uses cold-chemically bonded sands, ideal for complex, large-scale castings or small production batches.

When is it best to choose manual No Bake shaping?

It is suitable when complex geometries, high weights or non-standardized productions that require accurate manual control are required.

What is the maximum weight of castings that can be made?

In the No-Bake manual moulding department of the Fonderia Quaglia & Colombo, it is possible to produce castings up to 6 tons.

What advantages does it offer over automatic processes?

Greater flexibility, customization options, and direct control over every stage of the shape creation process.

Does No-Bake hand-shaping guarantee consistent quality?

Yes, thanks to the combination of staff experience, material control, and consolidated production processes.